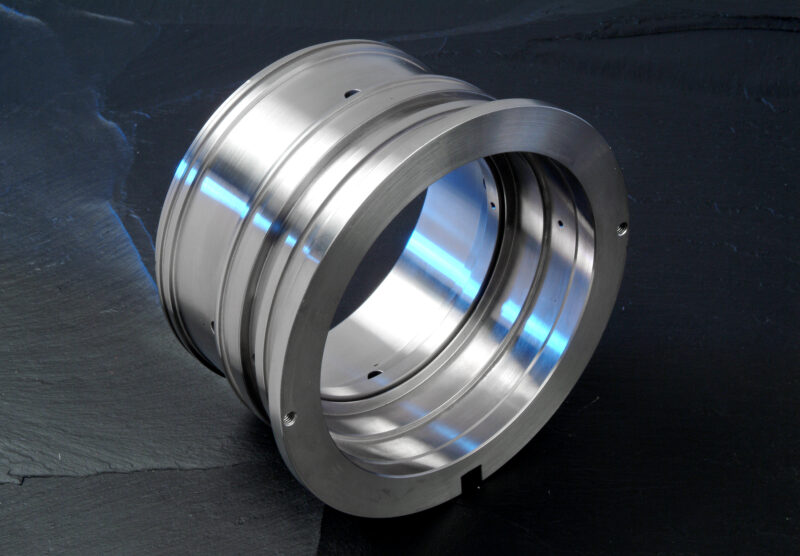

Sectors

Trusted by leading names, we deliver precision-engineered components for some of the world’s most demanding sectors.

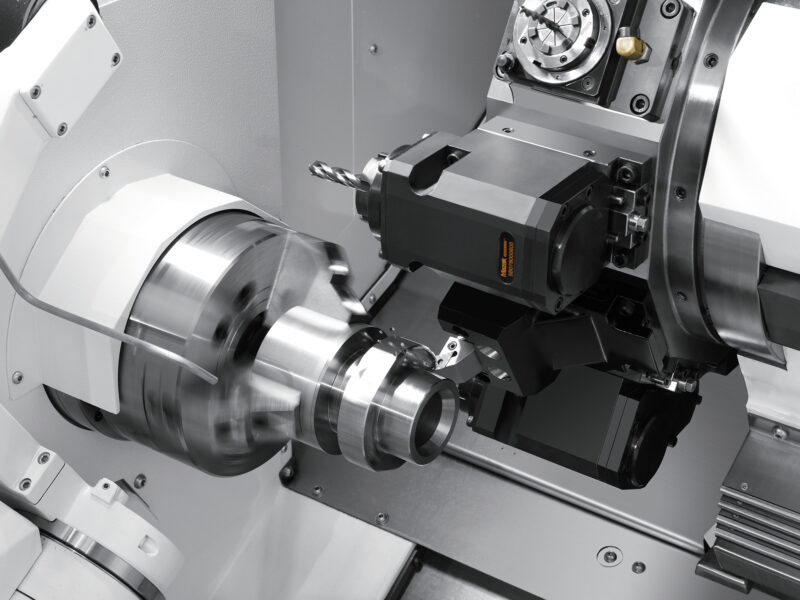

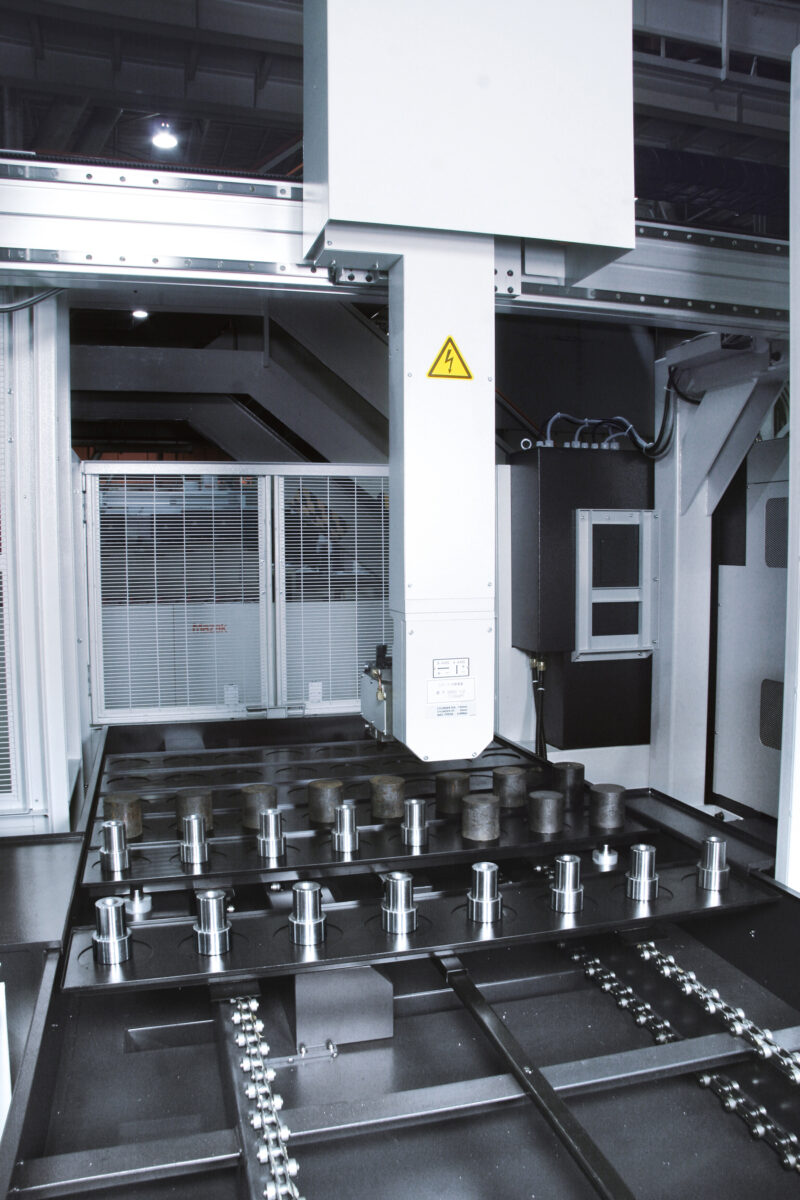

Capabilities

Delivering precision, efficiency and quality across every stage of production.

About GW Martin

Learn more about who we are, what we stand for and how we’ve built our reputation for excellence.