How surface finish can impact part performance

When it comes to precision engineering, the finer details make all the difference. Surface finish is one of those critical factors that can significantly influence a part's performance, durability, and functionality. But what exactly is surface finish, and why is it so important?

What is surface finish?

Surface finish, sometimes referred to as surface texture, describes the topographical characteristics of a component’s surface. These characteristics include the roughness, waviness, and lay pattern left after manufacturing processes such as machining, grinding, or polishing.

Surface finish is typically measured in micrometres (µm) and is assessed using tools like profilometers. The desired level of finish depends on the part’s application and operating environment.

The impact of surface finish on performance

A poor or inappropriate surface finish can compromise a part’s functionality in several ways. Below are some of the key areas where surface finish plays a vital role:

Friction and wear

Surface finish affects the level of friction between moving parts. A rough surface can increase friction, causing higher levels of wear and tear, which reduces the lifespan of components. For example, in rotating machinery, a smoother finish on shafts and bearings minimises energy loss and improves efficiency.

Seal integrity

When components need to create a tight seal—such as in hydraulic or pneumatic systems—the surface finish is critical. A rough or uneven surface can prevent proper sealing, leading to leaks and system failures.

Fatigue resistance

Surface irregularities can act as stress concentrators, reducing a part's resistance to fatigue. By optimising the surface finish, engineers can enhance the durability and lifespan of components that are exposed to cyclic stresses, such as turbine blades or engine components.

Corrosion resistance

Rough surfaces with microscopic valleys can trap moisture, debris, or chemicals, accelerating corrosion. A smoother surface finish helps prevent these issues, making the component more resilient in harsh environments.

Aesthetic appeal

Although not directly related to performance, the surface finish can influence the perceived quality of a product. High-end parts or consumer-facing components often require a polished finish for both functionality and appearance.

Surface finish in precision engineering

At GW Martin, we understand that the right surface finish is vital to meeting our customers' specifications and ensuring their parts perform as intended. Our advanced machining and inspection capabilities allow us to achieve precise finishes tailored to a range of industries, including aerospace, automotive, and medical.

By investing in the latest equipment and technologies, we can produce components with surface finishes that meet the most demanding standards.

Looking for a precision manufacturing partner to support you with your next project? Get in touch with our team today on 02380 642922 or email This email address is being protected from spambots. You need JavaScript enabled to view it..

How does CNC machining work?

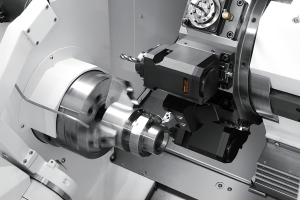

CNC machining, short for Computer Numerical Control machining, is renowned for being one of the most popular high-tech methods of digital manufacturing that has completely transformed the engineering industry.

In this blog, we’ll explore how CNC machining works and the benefits of using CNC machining for your next project:

What is CNC machining?

CNC machining is a manufacturing process in which pre-programmed computer software automates, monitors and controls the movement of CNC machinery.

Unlike 3D printing, which builds objects layer-by-layer, CNC machining is a form of subtractive manufacturing, using written code to remove material and shape the final product.

How CNC machining works

CNC machining makes pre-programming the machine’s speed and position functions possible, running them through software in consistent cycles. The process includes:

Step 1: Designing the part

The first step involves creating a detailed 2D or 3D design of the part to be manufactured using CAD (Computer-Aided Design) software, which acts as a blueprint for the CNC machine.

Step 2: Converting to a CNC programme

Programmers convert the CAD design file into computer code, typically G-code, for the CNC system to understand and execute the machining process.

This code is transformed into a CNC programme, often using CAM (Computer-Aided Manufacturing) software, allowing control over speed, feed rate and coordination.

Step 3: Setting up the machine

Before starting the machining process, the CNC machine undergoes meticulous set up. This includes securing the workpiece, selecting and installing the appropriate tools and loading the CNC programme.

Subsequently, the operator conducts a trial run to verify there are no errors in the coding.

4. Machining the part

The CNC machine follows the programmed instructions to control the cutting tools, which move along various axes to shape the workpiece. This process is highly precise and can involve multiple tools and operations like drilling, milling and turning.

The CNC machining starts with a block of material, called a blank, and uses fast-moving cutters to quickly carve away material and create the finished part. It carries out the dimensional tasks as specified, much like a robot.

Top 6 advantages of CNC machining

Precision

CNC machines operate with extreme accuracy, capable of producing parts with tight tolerances. Consistency Once programmed, CNC machines can produce numerous parts with exact uniformity. The process allows for consistency that would be difficult, if not impossible, to replicate manually.

Flexibility

Changing the production from one part to another is relatively simple, allowing for efficient small-batch production runs or large-scale production.

Speed

CNC machining can produce parts quickly, significantly reducing production times compared to traditional methods, for ultimate productivity.

Automation

The production of parts via pre-programmed software is mostly automated, requiring minimal intervention from users.

Suitable for a wide range of sectors

Essentially, there are no limits to what you can achieve with CNC machining.

At GW Martin, we are proud to have extensive industry experience working across multiple sectors, including:

- Defence

- Aerospace

- Automotive

- Medical

- Commercial

For a trusted precision manufacturing partner using the latest cutting-edge technology, call our expert team on 023 8064 2922 or email This email address is being protected from spambots. You need JavaScript enabled to view it..

GW Martin feature in Machinery Magazine

G W Martin feature in Machinery Magazine December issue

Andrew Allcock, Machinery Magazine Editor, visited us in December to report on our fast growing capabilities; including Assembly, Design for Manufacture and Supply Chain Management.