GW Martin visits 10 Downing Street: Championing apprenticeships & SME growth in the defence sector

This week marked a proud moment for GW Martin as we had the incredible opportunity to visit 10 Downing Street for a careers fair, as mentioned in the Daily Echo and Yahoo News, bringing along three of our talented apprentices - Michael, Drew, and Josh.

This prestigious event not only showcased the vital role of apprenticeships in the manufacturing and engineering industries but also reinforced the government’s commitment to supporting SMEs like ours.

A platform for growth & opportunity

Prime Minister Keir Starmer has unveiled a new hub to support SMEs, boosting investment opportunities for small firms across the UK. This initiative aligns with the government’s commitment to increasing defence spending to 2.5% of GDP by 2027, a move the Prime Minister highlighted in his LinkedIn post.

For companies like GW Martin, already embedded in the UK’s defence supply chain, this investment marks a significant step in strengthening manufacturing capabilities and expanding opportunities in the sector.

Empowering the next generation & strengthening SME support in defence

A key focus of our visit was the celebration of apprenticeships and their role in shaping UK manufacturing. Representing GW Martin, Michael, Drew, and Josh joined other young engineers in discussions with industry leaders and policymakers. Their participation underscored the importance of skills development in securing the future of the sector.

The Prime Minister’s announcement signals promising developments for SMEs in the defence industry. As a key supplier to the Armed Forces, GW Martin welcomes initiatives that drive investment, innovation, and collaboration. Our Managing Director, Stuart, recently spoke to the Daily Echo about how this commitment could open new doors for SMEs, ensuring businesses like ours continue to deliver precision engineering excellence.

A bright future ahead

With increased government backing for defence manufacturing, the future looks strong for SMEs driving innovation.

We look forward to seeing these policy changes translate into real opportunities. As always, we remain dedicated to precision engineering excellence, supporting the next generation of skilled professionals, and playing our part in strengthening UK industry.

Supporting those who serve: GW Martin signs the Armed Forces Covenant

At GW Martin, we are proud to announce the signing of the Armed Forces Covenant, solidifying our commitment to supporting those who serve or have served in the Armed Forces, as well as their families.

"As a company, we are deeply committed to supporting our Armed Forces community," says Stuart Yalden, Managing Director of GW Martin. "We recognise the sacrifices made by those who serve and their families, and we are proud to do our part in honouring their contributions. Signing the Armed Forces Covenant is not just a statement of intent; it’s a pledge to uphold the values of fairness, respect, and support for those who have given so much for our country."

Through this commitment, we aim to promote the Armed Forces Covenant across our business and community, offer employment support to veterans and reservists, and collaborate with local Armed Forces charities to enhance their outreach efforts.

Find out how you can support them by visiting their website: www.armedforcescovenant.gov.uk.

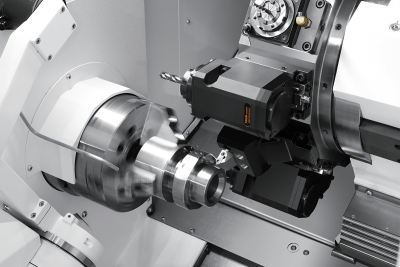

How surface finish can impact part performance

When it comes to precision engineering, the finer details make all the difference. Surface finish is one of those critical factors that can significantly influence a part's performance, durability, and functionality. But what exactly is surface finish, and why is it so important?

What is surface finish?

Surface finish, sometimes referred to as surface texture, describes the topographical characteristics of a component’s surface. These characteristics include the roughness, waviness, and lay pattern left after manufacturing processes such as machining, grinding, or polishing.

Surface finish is typically measured in micrometres (µm) and is assessed using tools like profilometers. The desired level of finish depends on the part’s application and operating environment.

The impact of surface finish on performance

A poor or inappropriate surface finish can compromise a part’s functionality in several ways. Below are some of the key areas where surface finish plays a vital role:

Friction and wear

Surface finish affects the level of friction between moving parts. A rough surface can increase friction, causing higher levels of wear and tear, which reduces the lifespan of components. For example, in rotating machinery, a smoother finish on shafts and bearings minimises energy loss and improves efficiency.

Seal integrity

When components need to create a tight seal—such as in hydraulic or pneumatic systems—the surface finish is critical. A rough or uneven surface can prevent proper sealing, leading to leaks and system failures.

Fatigue resistance

Surface irregularities can act as stress concentrators, reducing a part's resistance to fatigue. By optimising the surface finish, engineers can enhance the durability and lifespan of components that are exposed to cyclic stresses, such as turbine blades or engine components.

Corrosion resistance

Rough surfaces with microscopic valleys can trap moisture, debris, or chemicals, accelerating corrosion. A smoother surface finish helps prevent these issues, making the component more resilient in harsh environments.

Aesthetic appeal

Although not directly related to performance, the surface finish can influence the perceived quality of a product. High-end parts or consumer-facing components often require a polished finish for both functionality and appearance.

Surface finish in precision engineering

At GW Martin, we understand that the right surface finish is vital to meeting our customers' specifications and ensuring their parts perform as intended. Our advanced machining and inspection capabilities allow us to achieve precise finishes tailored to a range of industries, including aerospace, automotive, and medical.

By investing in the latest equipment and technologies, we can produce components with surface finishes that meet the most demanding standards.

Looking for a precision manufacturing partner to support you with your next project? Get in touch with our team today on 02380 642922 or email This email address is being protected from spambots. You need JavaScript enabled to view it..

GW Martin are exhibiting at Southern Manufacturing & Electronics 2025!

We’re excited to share that GW Martin will be exhibiting at Southern Manufacturing & Electronics 2025 from 4th-6th February at Farnborough International Exhibition and Conference Centre for the 8th consecutive year!

One of the UK’s largest annual engineering and manufacturing events is back, gathering suppliers, manufacturers, and decision-makers to showcase the latest products, services, and innovations, along with expert-led seminars.

We’ll be on Stand F190, where you’ll have the chance to:

- Speak to our experienced engineers to discuss your requirements

- Bring your drawings to discuss machining solutions right there!

- Learn about our expertise in CNC machining, turning and milling

- Discover our cutting-edge technology and robust quality control process

GW Martin’s commitment to innovation and excellence has forged partnerships with demanding sectors across the UK and beyond. Whether cutting-edge solutions, expert advice, or just want to see what’s new in the industry, our team would love to meet you.

Drop by Stand F190 to learn more about how we can support your engineering and manufacturing needs. To find out more about the event and to register, visit the Southern Manufacturing & Electronics website.

We look forward to seeing you in February!

GW Martin will be exhibiting at Manufacturing Solutions UK Incorporating Make Measurement Matter 2025

We’re thrilled to announce that GW Martin will be exhibiting at the Manufacturing Solutions UK & Make Measurement Matter event, hosted by GTMA in partnership with the British Turned Manufacturers Association (BTMA). The event will take place at Yamazaki Mazak UK Ltd in Worcester on Wednesday 26th February 2025. It promises to be an unmissable day for everyone involved in the precision engineering, manufacturing, and measurement industries.

Some of the day's highlights include a keynote presentation by Mark Ridgway, OBE, Chairman & CEO of Group Rhodes. Attendees will also have the opportunity to tour the Mazak facility at 1:00pm, offering an exclusive behind-the-scenes look at their state-of-the-art operations.

We’re excited to be joining the list of exhibitors at this highly anticipated event, where we’ll be showcasing our expertise in precision engineering and component manufacturing. Our knowledgeable team will be on hand to answer any questions and discuss how our tailored solutions can support your upcoming projects.

Event Details:

- Date: Wednesday 26th February 2025

- Time: 9:00am – 3:00pm

- Venue: Yamazaki Mazak UK Ltd, Badgeworth Drive, Worcester, Worcestershire, WR4 9NF

If you haven’t already, get your free tickets on Eventbrite here.

More information about the event can be found here.

We look forward to seeing you there!

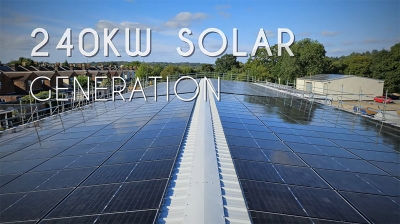

2024 Factory Refresh: Powering up production with solar energy

As we continue our 2024 Factory Refresh, we're excited to announce the completion of the next stage: increasing our solar energy capacity. With the help of the brilliant team at Empower Energy Ltd, we’ve reinstalled our original 150kW of panels and added an extra 90kW, bringing our total solar power generation to 240kW.

This upgrade means that during the summer months, we’ll be generating more energy across the 554 solar panels than we need for production, allowing us to export the surplus back to the grid. Even with 24/7 operations and the shorter winter days here in the UK, we expect to generate over 30% of our annual energy from solar power—around 170,000kWh per year. This will save an incredible 40,000kg of CO2 annually, taking us a significant step closer to Net Zero manufacturing.

Check out the timelapse to see the installation in action!

Our solar journey so far…

Solar power was first brought to GW Martin back in 2013, and since then, our original panels have produced 1.2 million kWh of clean energy. That’s the equivalent of saving 470 tonnes of CO2 emissions, or planting 14,000 trees! By upgrading our solar power system and implementing other energy-saving measures like air source heating and LED lighting, we’re continuing to reduce our energy usage and carbon footprint.

As a JOSCAR accredited business, we were one of the first companies to register for JOSCAR Zero to demonstrate our commitment towards Net Zero Manufacturing. These initiatives not only help the environment but also enable us to offer a sustainable supply of machined parts to our customers, while maintaining our ISO14001 accreditation.

2024 Factory Refresh: Check out our new roof!

That’s a wrap on the second stage of our big 2024 factory refresh – and we couldn’t be more excited about how things are shaping up. For those of you following along, we’re in the middle of a factory transformation that’s set to bring some major upgrades to our site in Eastleigh, Hampshire.

After installing a sleek new high-performance resin floor during the first stage, this latest project was all about giving our factory a brand new roof.

Kicking off this phase, we brought in the pros from Gemini Roofing and Cladding Ltd to handle the roof installation. With their careful planning and hard work, it was fully fitted just 8 days into our scheduled 2-week shutdown, which means there’s plenty of time to get the finishing touches sorted, including edge detailing, and prepare for our reopening on Monday 2nd September.

Even the weather decided to cooperate (mostly), with only one rainy day to contend with.

Heading into the next stage… Project Power

The new roof is only the latest chapter of the story of our factory refresh. We’re about to head onto the next phase, which we’ve dubbed ‘Project Power’.

As part of this, we’ll be reinstalling our solar panels back onto the roof, and even adding more solar power into the mix. We’re bumping up capacity by another 90kW, bringing us to a total of 240kW of solar energy generation. That means a third of our energy needs will be covered by the sun alone!

Our solar panels have been running for over 11 years now, and in that time, they’ve cranked out more than 1.2 million kWh of power. With this new upgrade, we’re excited to keep pushing toward a more sustainable future, powering our production with clean, renewable energy.

Next up, we’ll be diving into the solar panel installation and getting everything ready to harness that great British sunshine. Stay tuned for more updates as we continue to roll out these exciting changes.

2024 Factory Refresh: Kicking off with floor improvements

Here at GW Martin, our factory has come a long way since the original cam-auto workshop first opened its doors in 1967. We’ve always aimed to keep quality at the forefront of what we do, and through that have seen a significant evolution in our manufacturing methods. Keeping pace with modern machining demands means ensuring our workshop is equally up to the task, and we’ve always believed the foundation starts with the floor.

In 2015, we installed a resin floor that not only brightened the entire space but also provided a durable, easy-to-maintain surface. To kick off the start of our 2024 Factory Refresh, we seized the opportunity to relocate some machinery, allowing us to upgrade some of the areas that were previously missed.

This is just the first step in a series of planned enhancements designed to completely transform our production facilities – with a new roof and upgrades to our solar power to come. Stay tuned!

Celebrating 11 years of solar power at GW Martin

The solar panel system here at GW Martin has been running for 11 years!

Our busy factory uses a lot of electricity, so we’ve always been keen to explore ways in which we could reduce our impact on the environment. When taking into account our large roof area, it seemed a no brainer to make the most of this space, so we decided to install a 150kW Solar PV system back in 2013.

Since then, the results have been brilliant…

Over the last 11 years, we’ve generated 1.2 million kWh of power. This is equivalent to saving 470 tonnes in CO2 emissions, or planting 14,000 trees.

Most of the power generated has been used right here at our factory in Eastleigh, Hampshire to help us make over 10 million precision machined components. And what we haven’t used has been exported back to the grid. In fact, the 300,000 kWh that we’ve exported is enough to fuel making around 5 million cups of tea for British manufacturers!

Coupling our solar power system with other energy saving initiatives such as air source heating and LED lighting, we have been able to dramatically reduce our energy usage and carbon footprint. All of this helps us to provide a sustainable supply of machined parts for our customers and, in turn, supports our ISO14001 accreditation too.

GW Martin renews WEAF membership

We are delighted to maintain our membership of the West of England Aerospace Forum (WEAF).

WEAF is one of the largest aerospace and advanced engineering clusters in Europe, and serves as the leading networking association for aerospace and defence companies in the South West of England. Championing innovation and sustainability, WEAF plays a pivotal role in advancing the aerospace and defence industries.

The UK aerospace sector is the global leader, and WEAF actively supports a number of innovative programmes and industry projects, empowering us to deliver pioneering solutions and products. With a commitment to reducing carbon emissions by 78% by 2035, WEAF and its members remain dedicated to environmental sustainability.

Stuart Yalden, our Managing Director said: “We are immensely proud maintain our membership of WEAF. It is fantastic to have access to the latest insights and innovations, plus collaborate with industry experts, as we look to develop products to drive the aerospace and defence industries forward.”

For a reliable precision manufacturing partner equipped with the latest cutting-edge technology, call our expert team on 023 8064 2922 or email This email address is being protected from spambots. You need JavaScript enabled to view it..